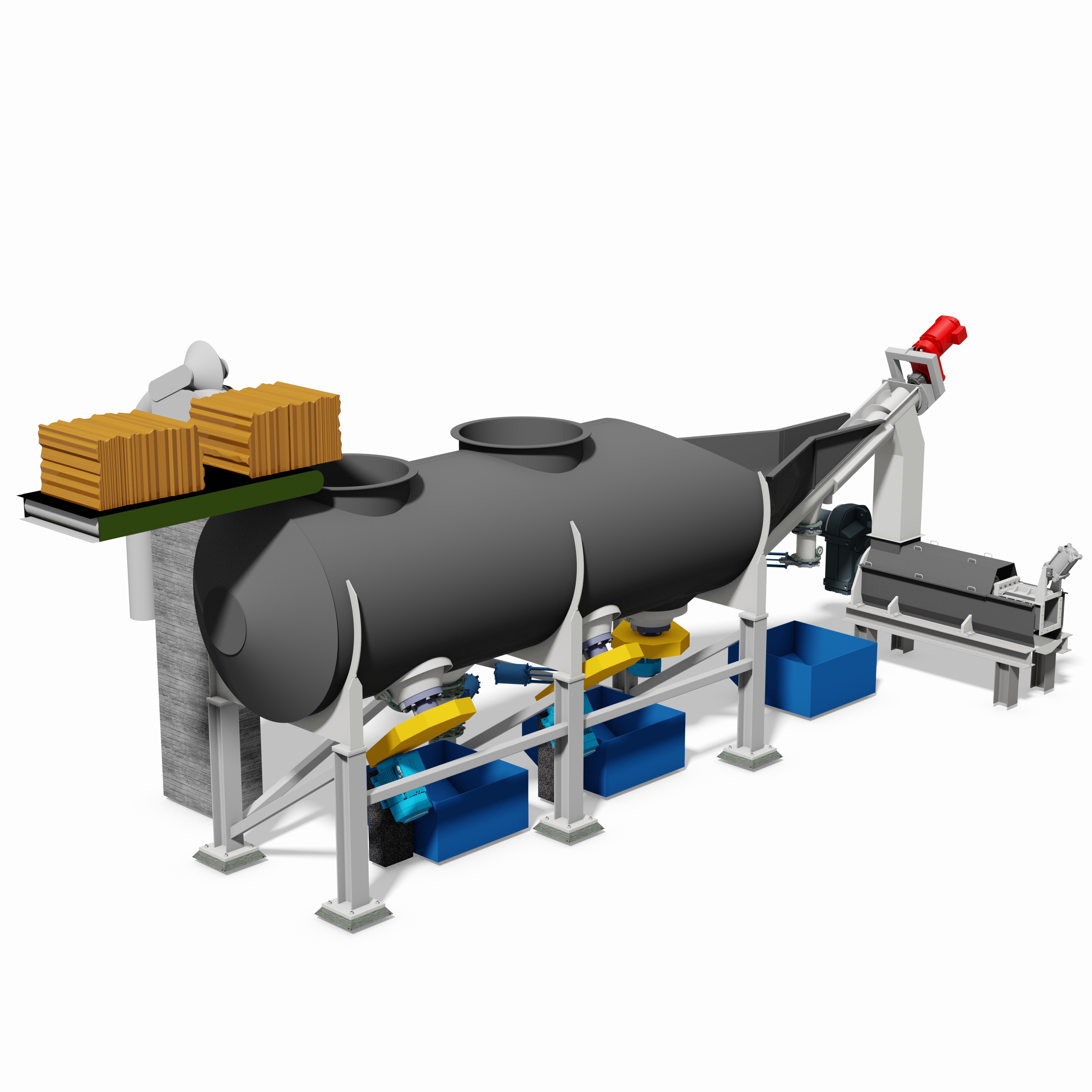

SimplyOne screen plate makes HC-cleaning and screening unnecessary for separating the bale wires in bale pulp lines

Uutiset

The slot width of the SimplyOne screen plate is about 2 mm, which brings a significant benefit to the processing of virgin bale pulp. The wire used in binding the pulp bales can get through the traditional perforated screen plates. This may cause damage in the further stock preparation process like in refiners.

”In bale pulp lines the SimplyOne screen plate keeps the bale wire pieces inside the pulper. The wire removal equipment after the pulper become unnecessary, and in new projects there is no need to invest in them at all", says PR Pulping Oy's sales manager Perttu Huusko.

He reminds that every additional device consumes energy, requires additional investments and equipment maintenance. In addition to lower investment and maintenance costs, SimplyOne screen plates also have significant energy saving potential.

The screen plates are always dimensioned accroding to customer’s needs and they can be installed in almost all existing pulpers. In addition to SimplyOne screen plates, PR Pulping supplies traditional screen plates as custom-made.