Typical problems and solutions in Conventional OCC pulping

Uutiset

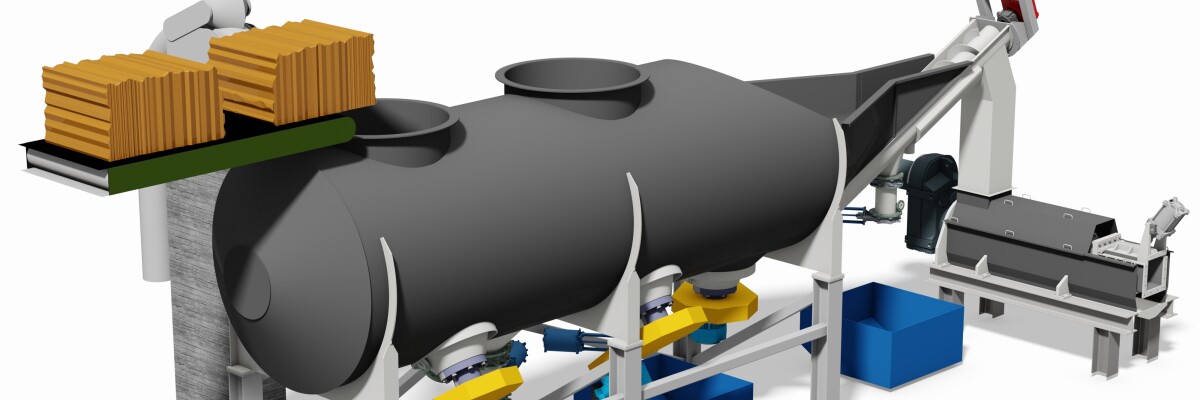

Here are some examples of the usual problems solved by SimplyOe concept:

Problem 1: You cannot get fiber free reject from the pulping station, because the cardboard is not completely disintegrated before the rejects are washed.

SimplyOne solution: In SimplyOne double pulper system the cardboard is given up to one hour of disintegration time. This ensures that all fibrous material is disintegrated before reject cleaning. Rotor rotating at the bottom of the reject washer further ensures that all the fiber is disintegrated and separated from the plastic. The dilution water needed in pulpers is first directed to reject cleaning. This method ensures that all the fibers can be collected.

Problem 2: Circulating the heavy rejects increases the wearing of screen plates and rotors.

SimplyOne solution: Coarse, abrasive material does not return to the pulpers thanks to SimplyOne's screen plate technology and optimized reject removal. Only the filtrate from the reject washer is returned back to the pulper. SimplyOne reject washer includes the screen plate with 2 mm wide slots, so only the very smallest particles can get back into the pulper in addition to the fiber.

Problem 3: The plastic does not follow the reject flow of the pulper and therefore does not move forward and remains spinning in the pulper near the rotor vortex.

SimplyOne solution: All the plastic that comes into the pulper with the raw material moves forward in the SimplyOne process. Thanks to precisely designed solutions, plastic does not accumulate into the pulpers, but comes out of the process. In addition, there is a rake on the surface of the reject washer, which helps the plastic movement towards the inclined screw conveyor. Thanks to the solution, the pulpers do not need to be emptied of plastic.

Problem 4: Traditional OCC lines have separate coarse screening, HC-Cleaners and reject cleaning. Complex process consumes a lot of energy.

SimplyOne solution: SimplyOne Compact is a complete double pulper system with coarse screening, reject washing and heavy reject removal build in one horizontal vat. Separate coarse screening with HC-Cleaners is not needed after the SimplyOne process. This saves costs and improves energy efficiency and space efficiency.