SimplyOne is effective for pulping liquid packaging cardboards containing plastic & aluminum

Uutiset

"The high fiber yield from liquid packaging cartons is a good example of how widely the SimplyOne technology developed by PR Pulping promotes the use of various recycled raw materials", epmhasizes Göran Antila, CEO of PR Pulping Oy.

The reject content of liquid packaging cartons are high due to high amount of plastic and aluminum. This requires special properties from the pulper, such as sufficient volume, so that the fiber can be disintegrated effectively. If the proper disintegration is not achieved, the fiber will be lost along with the plastic and aluminum.

” There is enough volume in SimplyOne double pulper system to ensure that cardboard is given up to one hour of disintegration time. Rotor rotating at the bottom of the reject washer further ensures that all the fiber is disintegrated and separated from the plastic. In addition, all pulper dilution water is first used for washing the reject. By this way, the fiber yield becomes very high," says Antila.

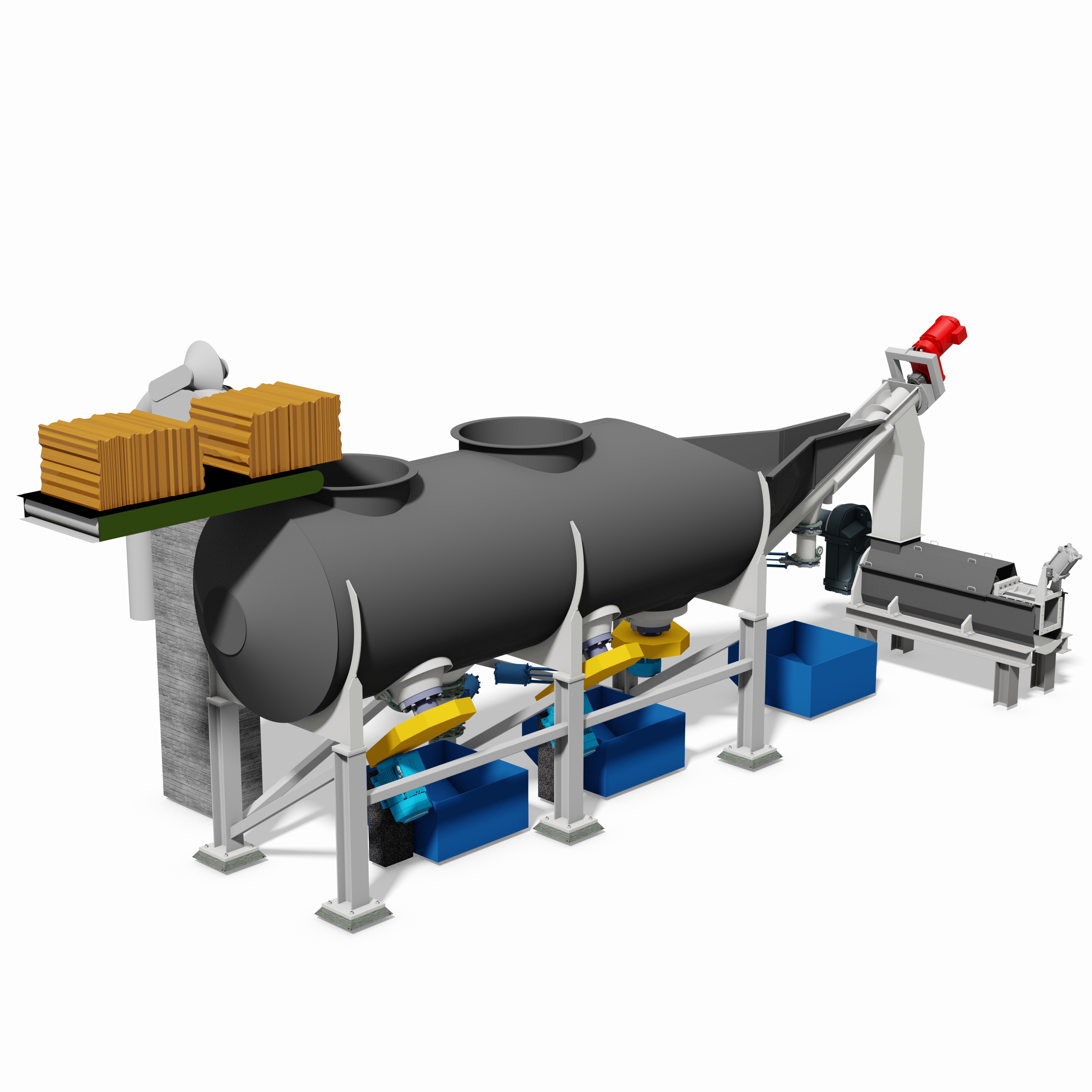

In addition to the fact that SimplyOne effectively separates the fiber from plastic & aluminum of the liquid packages, the technology is also very cost-efficient as well as energy-efficient. Traditionally the fiber yield has pursued to improve by adding more equipment to the process, but in the SimplyOne concept all the main functions are in the same horizontal vessel. As a result, fewer process pumps, piping, tanks, mixers, electrification and automation are required.

According to Göran Antila, SimplyOne's energy consumption is 30-50 % lower compared to the traditional recycled fiber process. 15-20 % savings can be achieved in maintenance costs, and the simple technology is also very reliable.