Cost- and energy-efficient technology by PR Pulping

Uutiset

” When a cleaner fiber has been desired, the goal has traditionally been achieved by adding new equipment to the process. In the SimplyOne concept, the solution is instead to simplify the process. If you manage to remove, for example, one intermediate tank from the process, you also remove the agitator, pump with electric motor, piping, valves, control loops and building volume. In other words, we can give up precisely those things that do not add value to the final product”, says PR Pulping Oy CEO Göran Antila.

In addition to SimplyOne enabling a high fiber yield, the simplified and improved technology is cost-effective and environmentally friendly. Göran Antila lists, among other things, the following benefits:

- 30-50% lower energy consumption compared to the traditional recycled fiber process

- small space requirements

- simple technology improves operational reliability

- coarse, abrasive material does not get back into circulation

- 15-20% savings on maintenance costs

- separated fiber is directly suitable to fine screening

"A more simple process always significantly saves the customer's investment and operating costs and is also a sustainable solution for the environment", sums up Antila. He emphasizes that the SimplyOne technology is the result of long development work, which is based on strong practical experience and expertise in pulp processing.

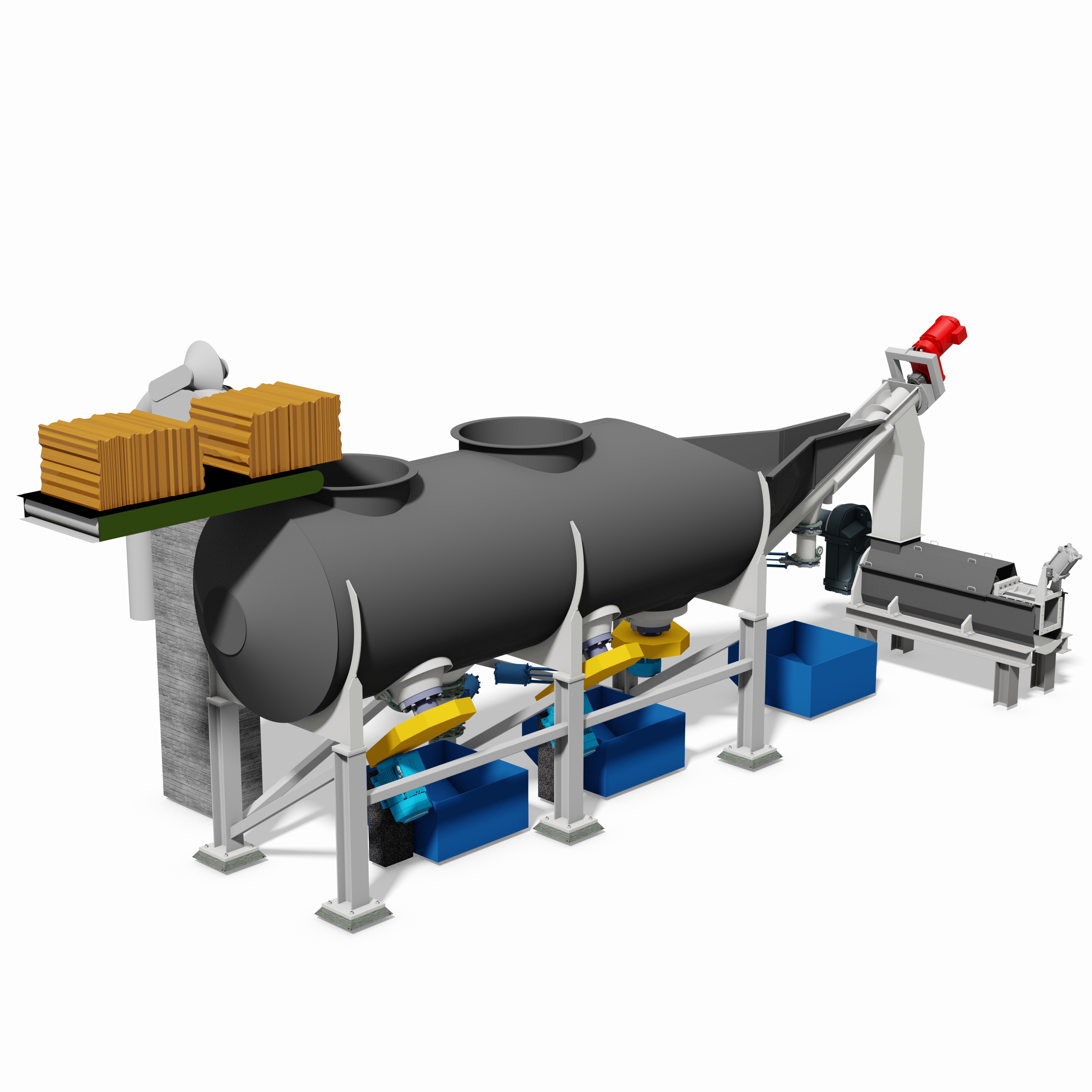

Antila mentions a under machine broke pulper with the round shaped vat as an example of development work. Less support structures are needed with round shaped vat. In addition to that, the pulp movement is smoother without excess vibrations and the vortex of inclined rotor rises towards the surface of the pulper, enhancing the sinking of the paper web.