Fiber Yield

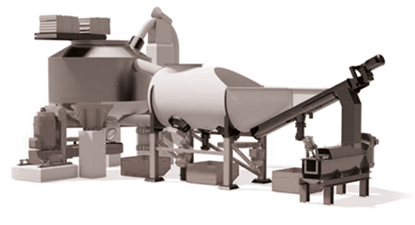

SimplyOne® Fiber Yield SOW

An independent unit designed for reject washing, which replaces the existing light and coarse reject screening.

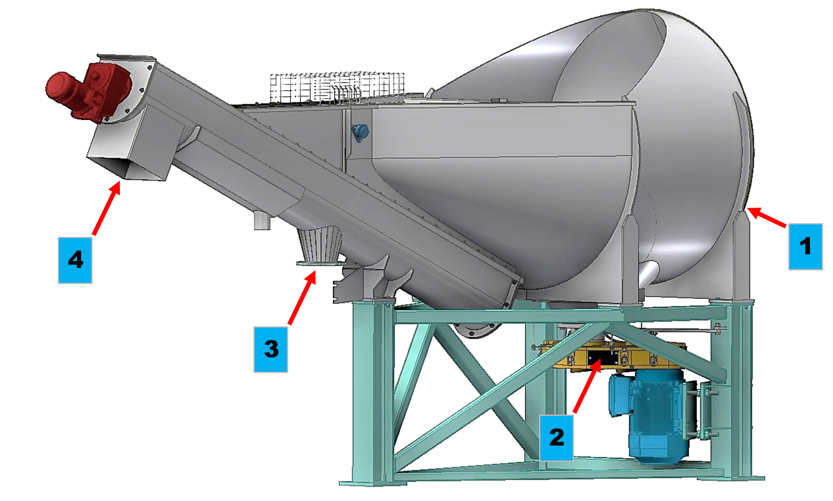

The fibrous material entering the washer is washed with dilution water for pulping. The fibrous water is pumped from the washer through a very fine screen plate to dilute the pulpers. SimplyOne® Fiber Yield's small apertured screen plate ensures that abrasive material is not recycled to wear the screen plates and rotors. The coarse and light reject is removed from the washer by a rising screw conveyor, at the end of which the reject is washed before it leaves for further processing. The heavy reject falls into the sand trap at the bottom of the screw conveyor.

The reject washer is able to decompose, for example, previously undegradable material, which means that the washer gives a better fiber yield than a traditional reject drum.

Reject washer operations

- Reject washing

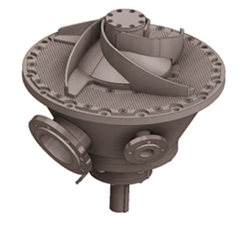

- Rotor unit

- Heavy reject removal

- Light reject removal

SimplyOne® Fiber Yield benefits

- Ability to break down any fibrous material

- Better fiber yield than with a traditional reject drum

- The screen plate prevents the abrasive reject from returning back to circulation